Coagulant composition for treating molds

阅读说明:本技术 用于处理模具的凝结剂组合物 (Coagulant composition for treating molds ) 是由 黄忠万 林秀娟 索拉亚·努尔·宾蒂·亚兹德 纳迪亚·马迪哈·宾蒂·拉姆利 于 2020-11-13 设计创作,主要内容包括:本发明涉及一种凝结剂组合物,用于处理用于制造胶乳产品的模具。所述凝结剂组合物包含抗粘剂,增滑剂,胶乳凝结剂和pH调节剂。所述抗粘剂包括多糖,不含基于硬脂酸酯的材料。将所述凝结剂组合物施用至所述模具并通过加热模具完成干燥。(The present invention relates to a coagulant composition for treating a mold for making a latex product. The coagulant composition comprises an anti-tack agent, a slip agent, a latex coagulant, and a pH adjuster. The anti-tack agent comprises a polysaccharide, free of stearate-based materials. Applying the coagulant composition to the mold and completing drying by heating the mold.)

1. A coagulant composition, the composition comprising:

i. an anti-sticking agent is added to the mixture,

a slip agent, wherein the amount of the slip agent,

a latex coagulant, and

a pH adjusting agent;

characterized in that the antisticking agent comprises a polysaccharide and is free of stearate-based materials.

2. A coagulant composition according to claim 1 comprising 0.005-2.000% by weight of the slip agent as a total solids content TSC.

3. The coagulant composition of any one of claims 1-2, wherein the slip agent comprises at least one of a silicone emulsion, polytetrafluoroethylene, and polyethylene glycol.

4. A coagulant composition according to claim 1 comprising a silicone emulsion having a total solids content of TSC of 0.010-0.050% by weight as the slip agent.

5. A coagulant composition according to claim 1 comprising 5.000-15.000% by weight of the latex coagulant with a total solids content of TSC.

6. The coagulant composition of any one of claims 1 and 5, wherein the latex coagulant comprises at least one of calcium nitrate, zinc nitrate, and calcium chloride.

7. A coagulant composition according to any of claims 1, 5 and 6 comprising calcium nitrate as the latex coagulant in a total solids content TSC of 7.000-10.000% by weight.

8. A coagulant composition according to claim 1 comprising 0.020-1.000% by weight of the pH adjusting agent as a total solids content TSC.

9. The coagulant composition of any one of claims 1 and 8, wherein the pH adjuster comprises at least one of ammonia, potassium hydroxide, and sodium hydroxide.

10. A coagulant composition according to any one of claims 1, 8 and 9 comprising ammonia as the pH adjuster at a total solids content of TSC of 0.030-0.050% by weight.

11. The coagulant composition of claim 1 comprising 0.500-5.000% by weight of the anti-tack agent as a total solids content TSC.

12. A coagulant composition according to claim 1 comprising as the anti-adherent a polysaccharide having a total solids content TSC of 1.000-3.000% by weight.

13. The coagulant composition of any one of claims 1 and 12, wherein the anti-tacking agent is at least one of a polysaccharide and a polyethylene wax.

14. A method (20) of treating a mold, the method comprising the steps of: a step (21) of washing the mould, a step (22) of applying a coagulant composition according to any one of claims 1-13 on a surface of the mould, and a step (23) of drying the coagulant composition.

15. The method (20) of claim 14, wherein the step of washing the mold (21) comprises: the mold is washed with an aqueous solution.

16. The method (20) according to claim 14, wherein the step (22) of applying the coagulant composition comprises: the form is immersed in the coagulant composition for 8-12 seconds.

17. The method (20) according to claim 14, wherein the step (22) of applying the coagulant composition comprises: the form is immersed in the coagulant composition for 9-10 seconds.

18. The method (20) of claim 14, wherein the coagulant composition is at a temperature range of 50-60 ℃.

19. The method (20) of claim 14 wherein the coagulant composition is at a temperature in the range of 55-58 ℃.

20. The method (20) according to claim 14, wherein the step (22) of applying the coagulant composition comprises: spraying the coagulant composition onto the surface of the mold.

21. The method (20) according to claim 14, wherein the step (23) of drying the coagulant composition comprises: the mold was heated in an oven at a temperature in the range of 100 ℃ and 200 ℃ for 45-180 seconds.

22. The method (20) of claim 21, wherein the mold is heated in the oven at a temperature in the range of 170 ℃ and 190 ℃ for 60-120 seconds.

23. A latex product (10) comprising at least one first layer (11) formed of a flexible material (13) and at least one second layer (12) formed on an outer surface of the first layer (11) to form an outer surface of the latex product (10), characterized in that the second layer (12) is formed of a coagulant composition (14) according to any one of claims 1-13.

24. The latex product (10) of claim 23, wherein said flexible material (13) comprises at least one of synthetic latex, natural latex, fabric, and plastic.

25. The latex product (10) of claim 24, wherein said synthetic latex compound comprises at least one of acrylonitrile-butadiene copolymer (NBR) latex, polychloroprene latex, Polyurethane (PU) latex, and Polyisoprene (PI) latex.

Technical Field

The disclosure made herein relates generally to the field of manufacturing latex products, and more particularly to a coagulant composition for treating a mold during the manufacturing of a latex product.

Background

Natural rubber has many desirable properties such as elasticity, comfort, fit, feel, durability and electrical resistance, and is therefore the most suitable material for wearable articles in many industries. At the same time, synthetic rubber is considered a better alternative to natural rubber because it is relatively more durable, more chemically resistant, free of allergens, i.e., latex proteins, can be used over a wider temperature range and has better weatherability.

Products made from latex (natural and synthetic) tend to adhere to any surface that comes into contact during manufacture and long term storage. As a solution to this problem, coagulant compositions with good blocking resistance are applied to the mold/former during the manufacture of the latex product.

A conventional coagulant composition is an electrolyte dispersion that, when mixed with a coagulant, causes the latex composition to coagulate. The coagulant composition is applied prior to latex dipping, and therefore, the coagulant must be dried prior to applying the latex. Also, the use of stearate based anti-tack agents in the coagulant tends to stain the surface of the mold.

Us patent No. us5534350a discloses a method of making a powder-free glove wherein a mould is required to be dipped into a coagulant composition containing a polyurethane polymer, then into a latex compound, and then into a latex compound and then into a polyurethane solution to form the glove without the use of any release powder or slip agent.

Typically, the coagulant composition comprises a stearate-based material as the primary anti-tack agent to prevent the latex product from adhering to other surfaces. After stripping the latex product, the stearate-based material tends to adhere to the mold and contaminate the surface of the mold, which can result in a very cumbersome mold cleaning process to remove the chemicals adhered to the mold. Without such a cumbersome mold cleaning process, the contaminated mold would affect the quality of the glove.

Accordingly, there is a need for a coagulant composition and latex product made therefrom that is free of stearate esters without compromising the desired properties of the latex product.

Disclosure of Invention

The present invention relates to a coagulant composition for treating a mold in the manufacture of a latex product. The coagulant composition includes an anti-tack agent, a slip agent, a latex coagulant, and a pH adjuster, and is free of stearate-based materials.

The mould is cleaned by washing with an aqueous solution. The coagulant composition is applied on the surface of the mold and dried by heating the mold in an oven. In a preferred embodiment, the coagulant composition comprises a polysaccharide as an anti-tack agent and silicon as a slip agent, wherein the polysaccharide is non-ionic and has a high freezing point, thereby achieving minimal or no residue sticking to the mold when the latex product is stripped from the mold and resulting in the retention of anti-blocking properties of the latex product after stripping the latex product while simplifying the mold cleaning process.

Drawings

The present invention will become more fully understood from the detailed description given herein below and the accompanying drawings, which are given by way of illustration only, and thus are not limitative of the present invention, and wherein:

in the drawings:

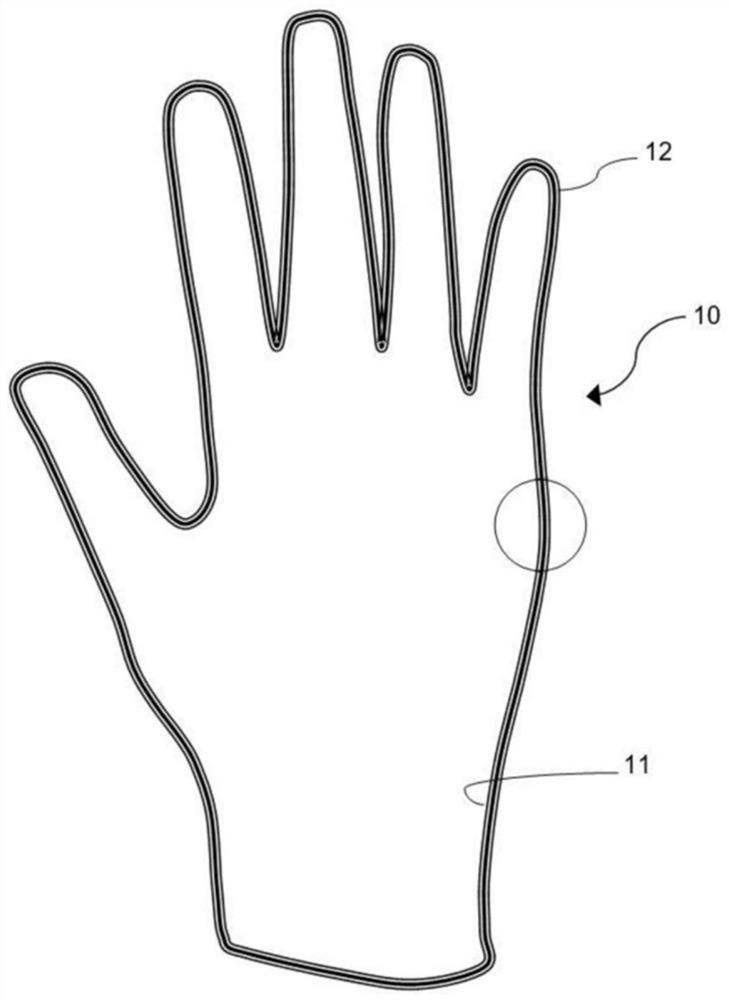

FIG. 1 shows a front view of a latex product according to an exemplary embodiment of the invention.

FIG. 1A shows an enlarged cross-sectional view of a portion of a latex product according to an exemplary embodiment of the invention.

Fig. 2 shows a flow chart of a method of processing a mold according to an exemplary embodiment of the present invention.

Detailed Description

Detailed descriptions of preferred embodiments of the invention are disclosed herein. However, it is to be understood that the embodiments of the present invention are merely exemplary, which can be embodied in various forms. Therefore, the details disclosed herein are not to be interpreted as limiting, but merely as the basis for the claims and as a basis for teaching one skilled in the art to variously employ the present invention. The numerical data or ranges used in the specification should not be construed as limiting. The following detailed description of the preferred embodiments will now be described, either individually or in combination, with reference to the accompanying drawings.

Various terms used herein are defined below. To the extent that the terms used in the claims are not defined below, those skilled in the relevant art are given the broadest definition persons in the pertinent art have given that term as reflected in printed publications and issued patents at the time of filing.

Defining:

latex-a stable dispersion of polymer microparticles in an aqueous medium. It may be naturally available or it may be prepared artificially by polymerizing monomers that have been emulsified with a surfactant.

Latex product-any product made from latex using a mold. It includes, but is not limited to, finger cots, condoms, wearable electronics, wearable medical devices, and the like.

Composition/formulation-a mixture of two or more chemical elements or compounds. It may be present in the form of a powder, liquid, emulsion, solution, dispersion, colloid, suspension, foam, gel, or the like.

Coating-a thin film that is uniformly deposited on a surface to cover the surface.

The present invention relates to a coagulant composition for treating a mold in the manufacture of a latex product. The coagulant composition comprises a combination of a polysaccharide as an anti-tack agent and silicon as a slip agent. The polysaccharide is non-ionic and has a high freezing point, and therefore, when the latex product is peeled from the mold, minimal or no residue adhesion to the mold is achieved, and results in the retention of the anti-blocking property of the latex product after peeling the latex product, while simplifying the cleaning process of the mold.

Referring to the drawings, FIG. 1 shows a front view of a latex product according to an exemplary embodiment of the invention. The latex product (10) comprises a first layer (11) formed of a flexible material (13) and a second layer (12) on an outer surface of the first layer (11). In a preferred embodiment, the flexible material (13) is a latex compound, such as acrylonitrile butadiene copolymer (NBR) latex. Alternatively, the latex compound is polychloroprene (CR) latex, Polyurethane (PU) latex, Polyisoprene (PI) latex or any other conventional synthetic latex. In an alternative embodiment, the flexible material may be natural latex, fabric, plastic, or the like.

The second layer (12) forms an outer surface of the latex product (10), as shown in fig. 1A, such that the second layer (12) comes into contact with any external object during use and/or storage of the latex product (10). The second layer (12) forms a film covering the outer surface of the first layer (11), wherein, in the manufacture of the latex product (10), the second layer (12) is applied to a mould and then the latex product (10) is turned inside out, as shown in figure 1.

The second layer (12) is formed from a coagulant composition (14), the coagulant composition (14) including an anti-tack agent, a slip agent, a latex coagulant, and a pH adjusting agent, and being free of stearate-based materials. In this way, the present invention enables the latex product (10) to be easily peeled from the mold in the process of manufacturing the latex product (10), and thus the anti-blocking property of the latex product (10) is maintained after peeling the latex product (10), while simplifying the cleaning process of the mold. The thickness of the second layer (12) is varied as desired by varying the period of time that the mould is immersed in the coagulant composition (14). Preferably, the form is dipped into the coagulant composition (14) for 5-15 seconds to form the second layer (12).

The proportions of the components of the coagulant composition (14) used to form the second layer (12) are given in the table below.

TABLE 1 proportions of the components in the coagulant composition

TSC-Total solid content

It is to be understood that the above components and ratios are only illustrative of the various embodiments of the present invention.

Fig. 2 shows a flow chart of a method of processing a mold according to an exemplary embodiment of the present invention. The method comprises the following steps: washing the mould (21), applying a coagulant composition (22) on the surface of the mould, and drying the coagulant composition (23).

The mold is cleaned by washing the mold with an aqueous solution comprising a detergent. Optionally, the mould is heated to remove liquid particles from the surface of the mould. Applying the coagulant composition to the surface of the form by immersing the form in the coagulant composition for 5-15 seconds. Preferably, the form is immersed in the coagulant composition for 9-10 seconds. The temperature of the coagulant composition is maintained in the range of 50-60 ℃. Preferably, the temperature of the coagulant composition is maintained in the range of 55-58 ℃. After application of the coagulant composition, the mold is dried by heating in an oven at a temperature of 100 ℃ and 200 ℃ for 45 to 180 seconds. Preferably, the mold is heated in the oven at a temperature of 170-190 ℃ for 60-120 seconds. Optionally, the coagulant composition is applied by spraying or any other conventional method for applying a coating of the coagulant composition on the surface of the mold. The mold then proceeds to a subsequent latex product manufacturing process.

The coagulant composition includes an anti-tack agent, a slip agent, a latex coagulant, and a pH adjuster, and is free of stearate-based materials. The anti-tack agent in the coagulant composition provides good anti-blocking without the use of stearate-based materials, thus avoiding contamination of the mold, thereby making the mold cleaning process simpler.

Finally, the resulting article is dried by heating in a final drying oven and then turned inside out to obtain the article (10 as shown in fig. 1) such that the second layer (12) forms the outer surface of the article (10) and the first layer (11) forms the inner surface of the article (10). Alternatively, the article (10) may also be prepared by forming the first layer (11) after the coagulant composition application step and drying step by any conventional method for preparing latex-based articles.

The following table shows the properties of the coagulant composition of the present invention compared to conventional coagulant compositions made using conventional coagulant compositions (samples 1, 2 and 3). From the properties listed below, it is apparent that gloves made using the coagulant composition of the present invention have higher thermal stability, smaller particle size, lower surface tension, and require lower concentrations of wash liquor to remove coagulant residue deposited on the mold surface. In addition, the latex products made using the present invention have lower powder content, higher grip levels and improved coefficients of friction. The lower powder content results in minimal or no sediment formation in the dipping tank containing the latex composition. In addition, the present invention is translucent, which indicates that there is no powder or stearate based material. Thus, the present invention is easier to clean.

TABLE 2 comparison of the inventive and conventional coagulant compositions

The terminology used herein is for the purpose of describing particular example embodiments only and is not intended to be limiting. As used herein, the singular forms "a", "an" and "the" may also be intended to include the plural forms as well, unless the context clearly indicates otherwise. The terms "comprises," "comprising," "including," and "having," are inclusive and therefore specify the presence of stated features, integers, steps, operations, elements, and/or components, but do not preclude the presence or addition of one or more other features, integers, steps, operations, elements, components, and/or groups thereof.

Unless specifically identified as an order of execution, the method steps, processes and operations described herein are not to be construed as necessarily requiring their performance in the particular order discussed or illustrated. It should also be understood that additional or alternative steps may be employed. The use of the expression "at least" or "at least one" implies the use of one or more elements, as such use may be in any of a number of embodiments to achieve one or more desired purposes or results.

- 上一篇:一种医用注射器针头装配设备

- 下一篇:防湿绝缘涂料及其应用