Fixing equipment for production and processing of sound screen

阅读说明:本技术 音响网罩生产加工用固定设备 (Fixing equipment for production and processing of sound screen ) 是由 麻霓霞 于 2021-09-02 设计创作,主要内容包括:本发明公开了音响网罩生产加工用固定设备,包括底板,所述底板的顶部开设有转动槽,所述转动槽的内表面滑动连接有滑动环,所述底板的顶部且位于滑动环的内部固定连接有固定环,所述固定环的周面开设有若干个滑槽,所述滑动环顶部的四周均转动连接有若干个转动短轴,通过在底板上设置能够转动的滑动环,而驱动组件中的自锁电机能够将动力传给滑动环,并带动滑动环进行转动,此时转动短轴上的弧形板在滑槽的作用下进行偏转,使得多个夹板向相对靠近的一侧进行运动,通过面接触的方式对其进行夹紧,能够有效的提高其固定的稳定性。(The invention discloses fixing equipment for producing and processing a sound mesh enclosure, which comprises a bottom plate, wherein a rotating groove is formed in the top of the bottom plate, a sliding ring is connected to the inner surface of the rotating groove in a sliding manner, a fixing ring is fixedly connected to the top of the bottom plate and positioned inside the sliding ring, a plurality of sliding grooves are formed in the peripheral surface of the fixing ring, a plurality of rotating short shafts are rotatably connected to the periphery of the top of the sliding ring, the sliding ring capable of rotating is arranged on the bottom plate, a self-locking motor in a driving assembly can transmit power to the sliding ring and drive the sliding ring to rotate, an arc-shaped plate on the rotating short shafts deflects under the action of the sliding grooves, a plurality of clamping plates move towards one side close to each other, the clamping plates are clamped in a surface contact manner, and the fixing stability of the clamping plates can be effectively improved.)

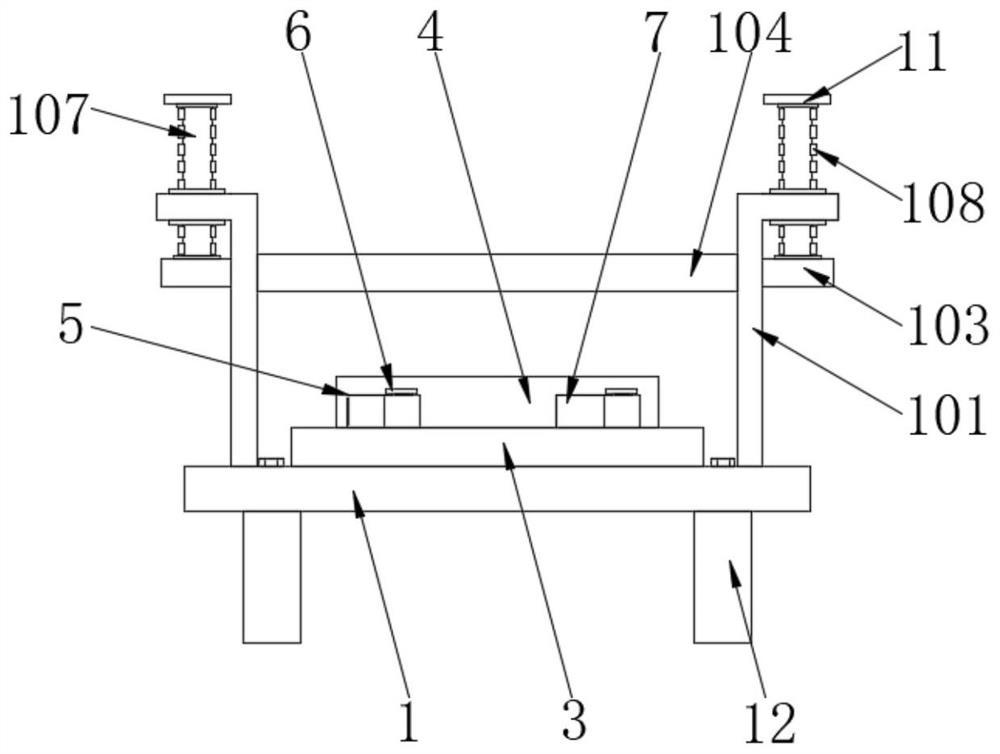

1. Fixing equipment for production and processing of sound box mesh enclosures comprises a bottom plate (1) and is characterized in that a rotating groove (2) is formed in the top of the bottom plate (1), a sliding ring (3) is connected to the inner surface of the rotating groove (2) in a sliding manner, a fixing ring (4) is fixedly connected to the top of the bottom plate (1) and located inside the sliding ring (3), a plurality of sliding grooves (5) are formed in the peripheral surface of the fixing ring (4), a plurality of rotating short shafts (6) are rotatably connected to the periphery of the top of the sliding ring (3), an arc plate (7) is rotatably connected to the outer surface of the rotating short shafts (6), a clamping plate (8) is rotatably connected to one end of the arc plate (7) through a connecting shaft, the outer surface of the arc plate (7) is slidably connected to the inner surface of the sliding grooves (5), and a driving assembly (9) is arranged on one side, located on the top of the bottom plate (1), of the sliding ring (3), the top of the bottom plate (1) is provided with a pressing component (10).

2. The fixing device for producing and processing the sound screen cover is characterized in that the driving assembly (9) comprises a plurality of gear teeth (91) positioned on one side of the sliding ring (3) and a self-locking motor (92) positioned at the bottom of the bottom plate (1), the output end of the self-locking motor (92) penetrates through the bottom plate (1) and extends to the outside of the bottom plate (1), the output end of the self-locking motor (92) is fixedly connected with a rotating gear (93), and the outer surface of the rotating gear (93) is meshed with the outer surface of the gear teeth (91).

3. The fixing equipment for producing and processing the sound screen cover according to claim 1, wherein the pressing component (10) comprises support plates (101) which are positioned at two sides of the bottom plate (1), a stroke groove (102) is symmetrically formed in one side of each support plate (101), a connecting rod (103) is slidably connected to the inner surface of each stroke groove (102), the connecting rod (103) is U-shaped, and two ends of each connecting rod (103) are fixedly connected with pressing rods (104).

4. The fixing equipment for producing and processing the sound screen cover according to claim 3, wherein a mounting sleeve (105) penetrates through the top of the supporting plate (101), limiting rings (106) are fixedly connected above and below the inner wall of the mounting sleeve (105), a limiting rod (107) is arranged on the inner surface of the mounting sleeve (105), the bottom end of the limiting rod (107) is fixedly connected with the top of the connecting rod (103), and a plurality of limiting blocks (108) are fixedly connected to the outer surface of the limiting rod (107).

5. The fixing device for producing and processing the sound screen cover according to claim 4, wherein the distance between two adjacent limiting blocks (108) is greater than the thickness of the limiting ring (106).

6. The fixing device for producing and processing the sound screen cover according to claim 4, wherein the thickness of the limiting block (108) is smaller than the height between the two limiting rings (106).

7. The fixing apparatus for producing and processing the sound screen according to claim 4, wherein a pressing plate (11) is fixedly connected to a top end of the limiting rod (107).

8. The fixing equipment for producing and processing the sound screen according to claim 1, wherein foot pads (12) are fixedly connected to the periphery of the bottom plate (1).

Technical Field

The invention relates to the technical field of sound screen processing, in particular to fixing equipment for sound screen production and processing.

Background

The sound box mesh enclosure mainly plays a role in dust prevention and protection for a common sound box, and the sound box mesh enclosure directly influences the processing quality of the sound box mesh enclosure in the processing process.

Chinese patent discloses a fixing device for production of sound net cover (publication No. CN213186562U), which includes a frame, an adjusting device, a rotating device, a pushing device and a fixing device, and fixes the stereo net cover, thereby improving the application range and avoiding obstructing the processing of the sound net cover.

Disclosure of Invention

The invention aims to provide fixing equipment for producing and processing an acoustic enclosure, which is characterized in that a rotatable sliding ring is arranged on a bottom plate, an arc-shaped plate on a rotating short shaft deflects under the action of a sliding chute, so that a plurality of clamping plates move towards one side close to each other, and are clamped in a surface contact mode, and the fixing stability of the fixing equipment can be effectively improved.

The purpose of the invention can be realized by the following technical scheme:

fixing equipment is used in stereo set screen panel production and processing, comprising a base plate, the rotation groove has been seted up at the top of bottom plate, the internal surface sliding connection who rotates the groove has the slip ring, the top of bottom plate just is located the solid fixed ring of inside fixedly connected with of slip ring, gu fixed ring global a plurality of spout has been seted up, all rotate all around at slip ring top and be connected with a plurality of and rotate the minor axis, the surface that rotates the minor axis rotates and is connected with the arc, the one end of arc is passed through the connecting axle and is rotated and be connected with splint, the surface of arc and the internal surface sliding connection of spout, the top of bottom plate just is located one side of slip ring and is provided with drive assembly, the top of bottom plate is provided with the compressing assembly.

As a further scheme of the invention: the driving assembly comprises a plurality of gear teeth and a self-locking motor, the gear teeth are located on one side of the sliding ring, the self-locking motor is located at the bottom of the bottom plate, the output end of the self-locking motor penetrates through the bottom plate and extends to the outside of the bottom plate, a rotating gear is fixedly connected to the output end of the self-locking motor, and the outer surface of the rotating gear is meshed with the outer surface of the gear teeth.

As a further scheme of the invention: the pressing assembly comprises supporting plates located on two sides of the bottom plate, travel grooves are symmetrically formed in one side of each supporting plate, a connecting rod is slidably connected to the inner surface of each travel groove, the connecting rod is U-shaped, and pressing rods are fixedly connected to two ends of the connecting rod.

As a further scheme of the invention: the utility model discloses a fixing device for fixing a car, including backup pad, installation cover inner wall, the top of backup pad is run through there is the installation cover, the equal fixedly connected with spacing ring in top and the below of installation cover inner wall, the internal surface of installation cover is provided with the gag lever post, the bottom of gag lever post and the top fixed connection of connecting rod, the outer fixed surface of gag lever post is connected with a plurality of stopper.

As a further scheme of the invention: the distance between two adjacent limiting blocks is larger than the thickness of the limiting ring.

As a further scheme of the invention: the thickness of the limiting block is smaller than the height between the two limiting rings.

As a further scheme of the invention: the top end of the limiting rod is fixedly connected with a pressing plate.

As a further scheme of the invention: foot pads are fixedly connected to the periphery of the bottom plate.

The invention has the beneficial effects that:

(1) according to the invention, the rotatable sliding ring is arranged on the bottom plate, the self-locking motor in the driving assembly can transmit power to the sliding ring and drive the sliding ring to rotate, at the moment, the arc-shaped plate on the rotating short shaft deflects under the action of the sliding groove, so that the plurality of clamping plates move towards one side close to each other, and are clamped in a surface contact manner, and the fixing stability of the clamping plates can be effectively improved.

(2) According to the invention, the two supporting plates are arranged on the bottom plate, the pressing rod capable of sliding up and down is arranged on the supporting plates and is matched with the limiting rod in the mounting sleeve, and the connecting rod can be fixed by utilizing the matching relation between the limiting block on the limiting rod and the limiting ring in the mounting sleeve, so that the pressing rod can press the sound screen cover below the connecting rod, the fixing stability of the sound screen cover can be further enhanced through the structure, and the sound screen cover is easy to popularize.

Drawings

The invention will be further described with reference to the accompanying drawings.

FIG. 1 is a schematic view of the overall structure of the present invention;

FIG. 2 is a top view of the outer structure of the base plate of the present invention;

FIG. 3 is a partial sectional view of the base plate of the present invention;

fig. 4 is a partial sectional view of the compressing assembly of the present invention.

In the figure: 1. a base plate; 2. a rotating groove; 3. a slip ring; 4. a fixing ring; 5. a chute; 6. rotating the short shaft; 7. an arc-shaped plate; 8. a splint; 9. a drive assembly; 91. gear teeth; 92. a self-locking motor; 93. a rotating gear; 10. a compression assembly; 101. a support plate; 102. a stroke slot; 103. a connecting rod; 104. a pressure lever; 105. installing a sleeve; 106. a limiting ring; 107. a limiting rod; 108. a limiting block; 11. a pressing plate; 12. a foot pad.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

Referring to fig. 1-4, the fixing apparatus for producing and processing a mesh enclosure for a sound box of the present invention includes a bottom plate 1, a rotating groove 2 is formed at the top of the bottom plate 1, a sliding ring 3 is slidably connected to an inner surface of the rotating groove 2, a fixing ring 4 is fixedly connected to the top of the bottom plate 1 and located inside the sliding ring 3, a plurality of sliding slots 5 are formed on a circumferential surface of the fixing ring 4, a plurality of rotating short shafts 6 are rotatably connected to a periphery of the top of the sliding ring 3, when the rotating groove 2 rotates inside the sliding ring 3, since the arc-shaped plate 7 is limited by the sliding slots 5, one end of the arc-shaped plate 7 can deflect under the action of the rotating short shafts 6, and when the rotating short shafts 6 and the sliding slots 5 are located at the same horizontal line, the arc-shaped plate 7 can make the extension length of the clamping plate 8 be longest, and the clamping plate 8 can clamp the mesh enclosure in a surface contact manner, the outer surface of the rotating short shaft 6 is connected with an arc-shaped plate 7 in a rotating mode, one end of the arc-shaped plate 7 is connected with a clamping plate 8 in a rotating mode through a connecting shaft, the outer surface of the arc-shaped plate 7 is connected with the inner surface of the sliding groove 5 in a sliding mode, a driving assembly 9 is arranged on one side, located on the sliding ring 3, of the top of the bottom plate 1, and a pressing assembly 10 is arranged on the top of the bottom plate 1.

In the invention, the driving assembly 9 comprises a plurality of gear teeth 91 positioned on one side of the sliding ring 3 and a self-locking motor 92 positioned at the bottom of the bottom plate 1, the self-locking motor 92 can realize self-locking to prevent the sliding ring 3 from sliding on the inner surface of the rotating groove 2 when the self-locking motor 92 is closed, the output end of the self-locking motor 92 penetrates through the bottom plate 1 and extends to the outside of the bottom plate 1, the output end of the self-locking motor 92 is fixedly connected with a rotating gear 93, and the outer surface of the rotating gear 93 is meshed with the outer surface of the gear teeth 91.

In the invention, the pressing component 10 comprises supporting plates 101 positioned at two sides of the bottom plate 1, stroke grooves 102 are symmetrically formed in one side of each supporting plate 101, a connecting rod 103 is connected to the inner surface of each stroke groove 102 in a sliding mode, the connecting rod 103 is U-shaped, two ends of each connecting rod 103 are fixedly connected with pressing rods 104, and the sound net cover is pressed from the upper side through the pressing rods 104, so that the fixing stability of the sound net cover can be further ensured.

According to the invention, the top of the supporting plate 101 penetrates through the mounting sleeve 105, the upper part and the lower part of the inner wall of the mounting sleeve 105 are fixedly connected with the limiting rings 106, the inner surface of the mounting sleeve 105 is provided with the limiting rod 107, the bottom end of the limiting rod 107 is fixedly connected with the top of the connecting rod 103, the outer surface of the limiting rod 107 is fixedly connected with the limiting blocks 108, and the pressure rod 104 on the connecting rod 103 can be fixed through the limiting relation between the limiting blocks 108 and the two limiting rings 106, so that the pressure rod 104 is prevented from being loosened and not pressing the sound mesh enclosure.

In the invention, the distance between two adjacent limiting blocks 108 is greater than the thickness of the limiting rings 106, and the thickness of the limiting blocks 108 is less than the height between the two limiting rings 106.

In the invention, the top end of the limiting rod 107 is fixedly connected with a pressing plate 11, the periphery of the bottom plate 1 is fixedly connected with foot pads 12, and the foot pads 12 are used for supporting the bottom plate 1 and preventing the self-locking motor 92 from contacting with the ground.

The working principle of the invention is as follows: at first place the sound screen panel in the inside of solid fixed ring 4, then start self-locking motor 92, thereby make rotating gear 93 rotate, through the meshing relation of rotating gear 93 and teeth of a cogwheel 91, make the slip ring 3 rotate at the internal surface of rotation groove 2, arc 7 at this moment swings under the spacing of spout 5, thereby make splint 8 move and contact with it to the one side that is close to the sound screen panel, stop self-locking motor 92 this moment, then hand pressing plate 11 and rotate 90, make stopper 108 follow spacing ring 106 and slide down, thereby transfer depression bar 104 downstream on connecting rod 103, after depression bar 104 compresses tightly the sound screen panel, rotating gag lever 107 through pressing plate 11, make stopper 108 change over into between two spacing rings 106, thereby accomplish the fixed to the sound screen panel.

In the description of the present invention, it is to be understood that the terms "upper", "lower", "left", "right", and the like, indicate orientations or positional relationships based on the orientations or positional relationships shown in the drawings, are only for convenience in describing the present invention and simplifying the description, and do not indicate or imply that the referred device or element must have a specific orientation and a specific orientation configuration and operation, and thus, should not be construed as limiting the present invention. Furthermore, "first" and "second" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance or implicitly indicating the number of technical features indicated. Thus, a feature defined as "first" or "second" may explicitly or implicitly include one or more of that feature. In the description of the present invention, "a plurality" means two or more unless otherwise specified.

In the description of the present invention, it should be noted that, unless otherwise explicitly specified or limited, the terms "mounted," "connected," and the like are to be construed broadly and may be, for example, fixedly connected, detachably connected, or integrally connected; can be mechanically or electrically connected; they may be directly connected or indirectly connected through an intermediate member, or they may be connected through two or more elements. The specific meanings of the above terms in the present invention can be understood in specific cases to those skilled in the art.

While one embodiment of the present invention has been described in detail, the description is only a preferred embodiment of the present invention and should not be taken as limiting the scope of the invention. All equivalent changes and modifications made within the scope of the present invention shall fall within the scope of the present invention.

- 上一篇:一种医用注射器针头装配设备

- 下一篇:一种不规则零件加工用固定装置